Maintenance Activities

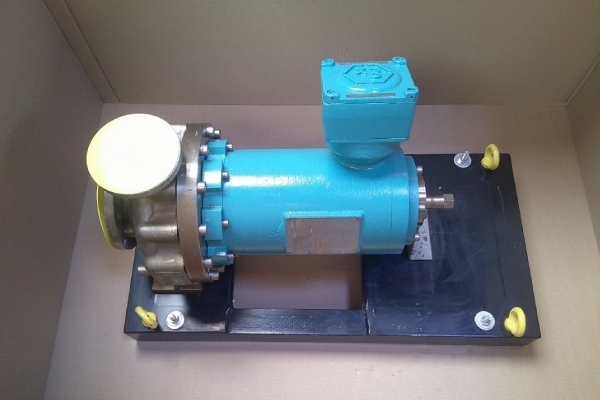

AFTER SALES SERVICE SEALLESS PUMP

You expect to send your pump for repair directly to our premises ? Our service department is there to help you. Optimex products, other brands or Wet Stator: Optimex takes care of repairing and maintaining all your waterproof pump products. Discover also our different repair points around the world.

Optimex has established efficient procedures maintenance for canned motor pump technology of all brands. Thanks to them we offer a qualitative repair in the shortest possible time.

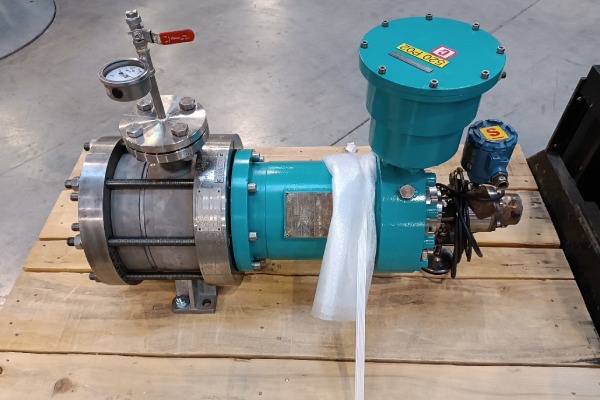

A maintenance operation at Optimex is divided into different phases:

- Phase 1: our experts carry out an expertise during dismantling and establish a first diagnosis. The components of the machine are tested and expertise according to a procedure established by Optimex. No component is neglected from the active part of the hydraulics to the electric motor elements, including all mechanical parts such as bearings, wear rings or the hydraulic balancing system.

- Phase 2: then we collect many operation and monitored data in order to establish a complete diagnosis.

- Phase 3: depending on the results of the expertise, our teams are led to propose different options. If the machine is partially damaged, we offer a replacement of the wearing parts identical to the original design. In case of recurring failures, we can make design improvements to make the pump more reliable. Finally, when repairs are no longer possible, Optimex can suggest retrofitting by reusing parts of the damaged machine or offering a new machine to substitute the damages one.

- Phase 4 : during reassembly and testing, the pumps follow the same manufacturing cycle as a new pump.

We inspect the complete mobile for roundness defects and balancing as well as axial clearance. We carry out a hydrostatic test and revalidate the hydraulic performances, power consumption and the balancing system reliability.

In order to continue to develop its quality as well as its reactivity, Optimex has purchased a three-dimensional control machine or has invested in its machining company by acquiring a CNC (Computer Numerical Control) machining center.

Optimex Products

SPECIALIST IN PUMP MAINTENANCE

Through its after-sales service, Optimex offers pump maintenance in its Fleurieux-sur-l’Arbresle workshop. Whether as part of preventive or corrective maintenance, our customers’ pumps are brought back to our premises for inspection and repair if any.

Throughout maintenance operations, the after-sales service communicates with customers to keep them informed.

Typical maintenance for an Optimex pump is as follows:

After receipt, the pump is dismantled and the various parts are inspected to assess their state of wear and understand the potential cause(s) of failure. This assessment is summarised in a report sent to the customer, which includes a list of repair operations and possible modifications, as well as the timeframe and total cost of maintenance.

Once the customer has agreed and placed the maintenance order, we organise the procurement of all parts from our suppliers, as well as the refurbishment of certain parts from our subcontractors. All this is done in collaboration with the purchasing department.

The pump is then reassembled and tested to ensure that it is leak-free and that its performance after maintenance meets the customer’s expectations. All pump reassembly operations are carried out in accordance with the various standards (ISO9001 / AtEx / API985) as part of

Optimex’s overall commitment to quality.

Finally, the pump is returned to the customer for recommissioning.

Other Brands

MAINTENANCE OF OTHER PUMP MANUFACTURERS

Optimex can take care of the repair and maintenance of pumps that were not manufactured by Optimex. To find out more about the possibilities, please contact us via the contact form or by phone.

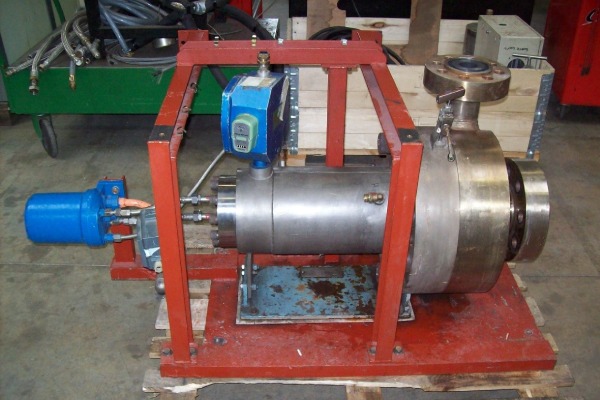

Wet Stator

SPECIALIST IN PUMPING SOLUTIONS

OPTIMEX is specialized in leak-proof pumping solutions to guarantee the security of the process. Naturally OPTIMEX has developed its know-how in the canned motor pump technology. Thanks to their double containment, this technology provides an absolute tightness with no leakage to the outside. The monobloc construction of these machines and the absence of any dynamic sealing ensure the highest level of security against the risk of leakage.

Optimex offers, among other things, wet stator repair for cryogenic, liquefied gas and other applications in its after-sales services. Optimex takes care of the repair of any type of wet stator. We deal with Optimex wet stators but also with the repair of wet stators of other brands.

To find out more about the possibilities, please contact us via the contact form or by phone.

Workshop in World

SPECIALIST IN INTERNATIONAL PUMP REPAIR

If your company would like to have your pump repaired by our experts but is unwilling or unable to send it to our workshops in France, Optimex has a solution for you. In order to reduce the travel time of your pump, Optimex proposes to send it to one of our partner workshops to whom we bring our expertise. Our different partner workshops are located in Germany, Canada, the United States and Malaysia.

To find out more about the possibilities, please contact us via the contact form or by phone.