Vertical Pumps

VERTICAL CENTRIFUGAL PUMP MANUFACTURER

Optimex has a wide range of single stage centrifugal hydraulics pumps and multi-stage centrifugal hydraulics pumps to use in different vertical configurations and a variety of applications.

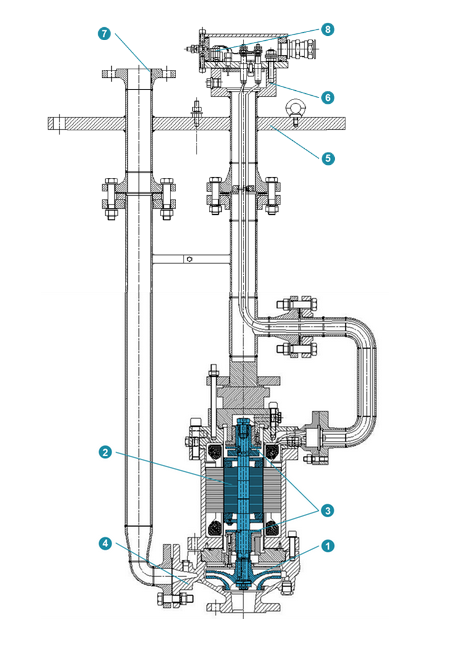

The major advantage of a vertical pump in submerged configuration is the elimination of the long shaft found on pumps with mechanical seals and magnetic drives. This makes it possible to install machines at depths of up to 30m.

Ideal for liquefied gas processes with NPSH and boiling phase problems, submerging the vertical pump unit avoids any vaporization problems within the equipment.

For applications with low-viscosity liquids, vertical orientation reduces load on bearings and optimizes lubrication.

Optimex is able to supply charge barrel for new installation, as well as to install a pump in an existing charge barrel.

Hung

CONSTRUCTION

- Construction: Single-stage or Multistage,

ISO 15783 and API685 - Flanges: According to

NF EN1092-1 or ASME B16.5 - Arrangements: Pit installation, charge barrel, on existing tank

MATERIAL

- Nodular cast iron (NCI)

- Stainless steel (SS)

- Carbon steel (CS), Low temperature carbon steel (LTCS)

- Duplex (Uranus U55)

- Code API S5, S6, S8, A8, D1

- Other materials on demand

FUNCTIONNING AT

- Flow: Up to 500 m3/h

- Head: Up to 900 m

- Frequency: 50 to 60 Hz or frequency variation

- Temperature: -135°C / 350°C

- Pressure design: Up to 50 bar

HAZARDOUS AREA

- Class temp T1 to T6

- Zone 1 to zone 2

- IECEx/ATEX/UL/CSA/CCC marking

Download our HUNG pump brochure:

Request a quote for the HUNG pump range:

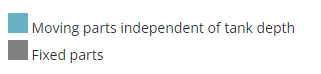

INRI

STANDARD CONSTRUCTION

1 Standard flanges according to EN 1092-1, ASME B16.5

2 Casing wear ring

3 Casing drain nut

4 Motor frame (secondary containment)

INSTRUMENTATION OPTIONS

A Control of the liquid temperature at the hottest point of the pump

B Winding overheat protection PT100 or/and PTC

C Control and monitoring of the second containment pressure: to detect the stator liner failure

D Control and monitoring of the mobile position, mounted on the rear bearing support: to detect any deviance of thrust balancing or bearings capacity

E Rotating direction indicator with local sensor: to guarantee the appropriate electrical connection

Other instrumentations can be supplied for your installation, such as liquid level switch, power controller, frequency converter…

IMPORTANT: Minimum requirement in hazardous area is liquid level control and temperature control.

CONSTRUCTION

- Construction: Single-stage, ISO 15783

- Flanges: According to

NF EN1092-1 or ASME B16.5 - Arrangements: Inline design

MATERIAL

- Stainless steel (SS)

- Other materials on demand

FUNCTIONNING AT

- Flow: Up to 100 m3/h

- Head: Up to 100 m

- Frequency: 50 to 60 Hz or frequency variation

- Temperature: -135°C / 350°C

- Pressure design: Up to 50 bar

HAZARDOUS AREA

- Class temp T1 to T6

- Zone 1 to zone 2

- IECEx/ATEX/UL/CSA/CCC marking

Download our INRI pump brochure:

Request a quote for the INRI pump range:

Vertical On Chair

CONSTRUCTION

- Construction: Single-stage or Multistage, ISO 15783 and API685

- Flanges: According to

NF EN1092-1 or ASME B16.5 - Arrangements: Vertical on chair

MATERIAL

- Nodular cast iron (NCI)

- Stainless steel (SS)

- Carbon steel (CS), Low temperature carbon steel (LTCS)

- Duplex (Uranus U55)

- Code API S5, S6, S8, A8, D1

- Other materials on demand

FUNCTIONNING AT

- Flow: Up to 500 m3/h

- Head: Up to 900 m

- Frequency: 50 to 60 Hz or frequency variation

- Temperature: -135°C / 350°C

- Pressure design: Up to 50 bar

HAZARDOUS AREA

- Class temp T1 to T6

- Zone 1 to zone 2

- IECEx/ATEX/UL/CSA/CCC marking

Vertical In Tank

CONSTRUCTION

- Construction: Single-stage or Multistage, ISO 15783 and API685

- Flanges: According to

NF EN1092-1 or ASME B16.5 - Arrangements: Pit installation, charge barrel, on existing tank

MATERIAL

- Nodular cast iron (NCI)

- Stainless steel (SS)

- Carbon steel (CS), Low temperature carbon steel (LTCS)

- Duplex (Uranus U55)

- Code API S5, S6, S8, A8, D1

- Other materials on demand

FUNCTIONNING AT

- Flow: Up to 500 m3/h

- Head: Up to 900 m

- Frequency: 50 to 60 Hz or frequency variation

- Temperature: -135°C / 350°C

- Pressure design: Up to 50 bar

HAZARDOUS AREA

- Class temp T1 to T6

- Zone 1 to zone 2

- IECEx/ATEX/UL/CSA/CCC marking