The Canned Motor Pump is composed of a traditional centrifugal hydraulic, connected to a special motor. There is no dynamic seals on the shaft giving a high reliability and the best MTBF of centrifugal pumps. Moreover, the double containment ensures a strong safety solution.

To satisfy our customers our entire range of canned motor pump is designed and manufactured in France, and tested according to our own standards and respectful of all French and European standards.

THE DIRECTIVES:

- Machine – 2006/42/EC

- Electric equipement – 2014/35/UE

- Electromagnetic compliances – 2004/108/CE

- ATEX – 2014/34/UE

- Pressure Equipement – 2014/68/UE

THE STANDARDS:

- Quality Management Systems ISO 9001:2015 & NF EN ISO

80079-34 - ISO 19443 certification

- End suction centrifugal pumps – ISO 2858

- Seallless Rotordynamic Pumps – ISO 15783

- Sealless Centrifugal Pumps for Petroleum, Petrochemical

and Gas Industry Process service – API 685 - Nuclear Plant Equipment – RCC- M/MX/MRX

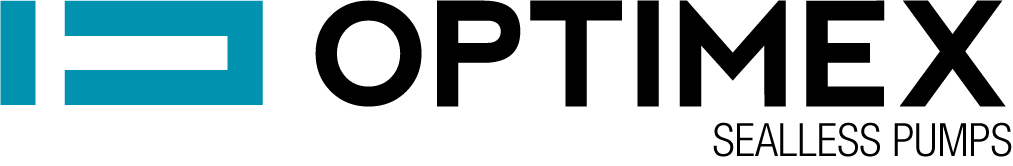

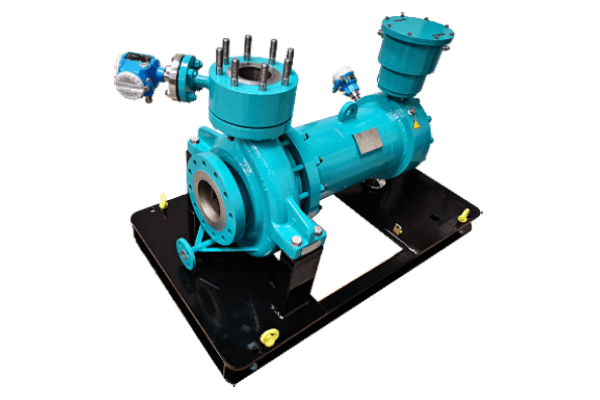

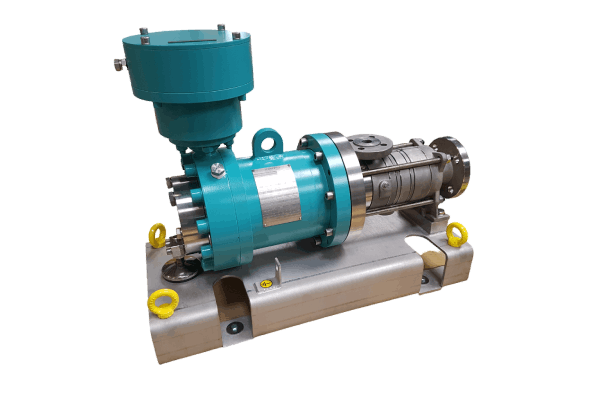

Horizontal Pumps

MANUFACTURER OF HORIZONTAL CENTRIFUGAL CANNED MOTOR PUMP

Standard horizontal centrifugal hydraulic with a single casing coupled with a canned motor.

MAIN BENEFITS OF THE HORIZONTAL PUMP:

- Simple machine design with only two slide bearings lubricated by the liquid

- Compact dimensions given by a monobloc assembly

- No linement at the installation

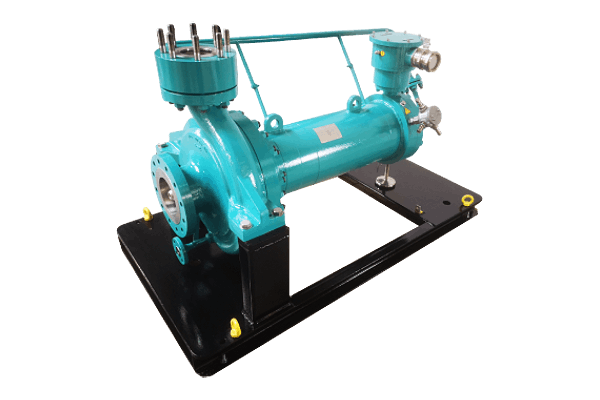

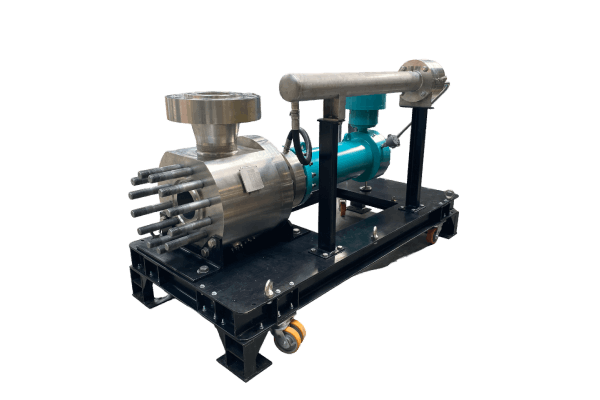

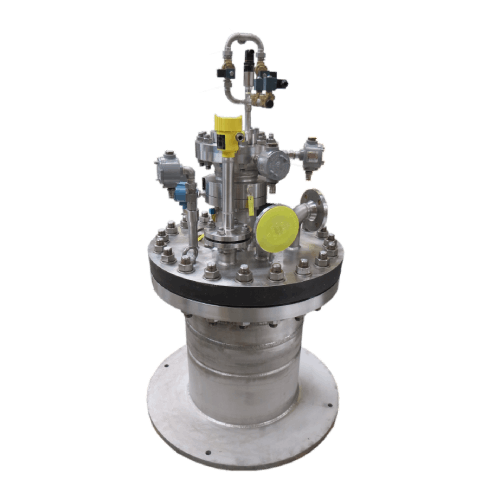

Vertical Pumps

MANUFACTURER OF VERTICAL CENTRIFUGAL CANNED MOTOR PUMP

Vertical pump arrangement for a variety of applications in different configurations:

- Install in existing or new charge barrel,

- Install in a tank or in pit,

- Submerged solution…

MAIN BENEFITS OF THE VERTICAL PUMP:

- No long shaft with guiding bearings

- No need of lubrification system : lubrication of the bearings with the pumped liquid

- No seals between the motor and soleplate

- Whatever the tank depth, rotating parts have reduced dimensions

- Space saving outside the tank, solution completely submerged

Self-Priming Pumps

MANUFACTURER OF SELF-PRIMING PUMP

Self-priming pump solutions at adapted process configurations.

OPTIMEX offers two solutions for pump installed above suction tank:

- Side channel pumps

- Self-priming pumps (pump with priming pot on the body)

These industrial pumps allow the creation of a partial vacuum at the pump suction, which eliminates air from the suction line.

For both types of industrial centrifugal pumps, it is necessary to fill the pump before the first start-up.

MAIN BENEFITS OF THE SELF-PRIMING PUMP:

- Starting possible when the pump is installed above suction tank

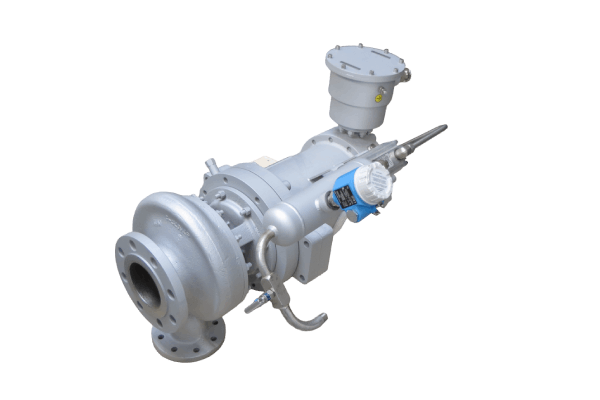

High Pressure Pumps

MANUFACTURER OF HIGH PRESSURE PUMP

Design pressure of the high-pressure pump exceeds 50 bar up to 400 bar.

MAIN BENEFITS OF THE HIGH PRESSURE PUMP:

- Workable with high static suction pressure

- Avoid dynamic seals

High Extreme Temperature Pumps

MANUFACTURER OF HIGH EXTREM TEMPERATURE PUMP

Design temperature of the high extreme temperature pump exceeds 400°C.

MAIN BENEFITS OF THE HIGH EXTREM TEMPERATURE PUMP:

- Avoid dynamic seals

- No external leakage

Custom Solution

SPECIALIST IN TAILOR MADE PUMPING SOLUTIONS

Special pump design to comply with customer arrangement by fitting place or retrofitting of excisting hydraulic.

MAIN BENEFITS OF THE CUSTOM SOLUTION PUMP:

- Maintain existing hydraulic parts or interfaces on installation

- No modification on process side

- Maintain existing interfaces on process side

- Recent pump unit adapted to canned motor construction

- Standardisation of spare parts with Optimex products range

- Increase reliability and safety of pumping unit

- Reduce maintenance costs