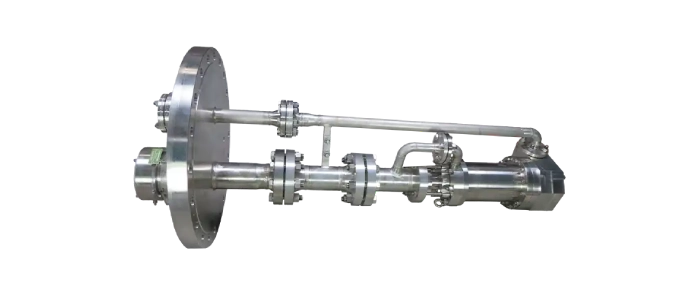

Nuclear Pumps

RADIOACTIVE LIQUIDS PUMP MANUFACTURER

The operation of a nuclear facility necessarily involves the use of critical environments with extreme temperature, radiations, or magnetic fields, that are hazardous to humans and the environment. OPTIMEX canned motor pumps are particularly well suited to this type of liquid since their double containment and the absence of dynamic sealing reduce the risk of leakage to a minimum. As a result, OPTIMEX canned motor pumps successfully maintain the integrity safety function. Canned motor pumps for radioactive liquids also ensure that the operability safety function is maintained over time thanks to the absence of friction under normal operating conditions and therefore a lower failure rate and fewer maintenance operations.

Examples of nuclear process:

- Primary water and drain

- Secondary coolant

- Borated water and boric acid

- Demineralised water

EVU Containment heat removal system

RPE Nuclear vent and drain system

PTR Fuel pool cooling (and purification) system

REA Reactor boron and water make-up system

TEP Coolant storage and treatment system

TEU Liquid waste processing system

TRI Effluent treatment building closed cooling water-system

MDB Liquid effluent loop beta/gamma) / REU Recirculation loop

DRS Draining and Refilling System

DRG Duct rupture detection loop